Hydroxypropyl methyl cellulose (HPMC) is a water-soluble ether with excellent performance, which is made of natural polymer material cellulose and processed by a series of chemicals. HPMC can be used in construction materials, the coating industry, ceramics, medicine, food, textile, agriculture, daily chemicals, and other industries.

The role of Hydroxypropyl methyl cellulose in construction materials:

Workability

With the addition of HPMC, the workability of construction materials is significantly improved. For example, mortar without the addition of HPMC is looser and easier to lose water, while with the addition of HPMC, the surface of mortar is smooth and tightly bonded to the substrate, which prolongs the use time and is suitable for large buildings.

Water retention

Cement or gypsum-based products undergo a hydration reaction with water, so these products can have a certain strength. If there is no water, the reaction will not occur and there will be no strength. High-quality HPMC disperses uniformly and effectively in cement mortar and gypsum-based products, sealing all solid particles and forming a wetting film. The water in the matrix is gradually released over time and forms a hydrate with the inorganic cementitious material, resulting in water retention. ( The most important role of HPMC is to increase building materials’ water retention and improve their bond strength. )

Adhesive

By adding HPMC, the bonding ability of cement mortar and gypsum-based products is significantly improved, which can ensure that the tiles will not slip off and that the gypsum and the substrate are firmly bonded together. However, the amount of HPMC added should not be too much, on the one hand, the material will be sticky and glued to the construction tools, causing inconvenience to the construction, and on the other hand, the material will appear with hollow gaps. If you can not ensure the amount of HPMC that needs to add or the viscosity of HPMC, you can consult our experts, we will contact you as soon as possible.

Extend the open time

HPMC can be used as a retarder for building materials (such as mortar, plaster, etc.). If you don’t need a particularly long construction time, the retarding effect of HPMC is enough to meet your user’s needs.

Air-entraining agent

After adding HPMC, many tiny bubbles will be generated inside the material, just like a honeycomb structure. Small bubbles act as “lubricant” and can have very good building performance. In addition, the honeycomb structure can prevent water penetration by blocking the capillary phenomenon caused by the hardening of the original cement, making the walls, tiles, cracks, etc. with a good waterproof effect. The effect of the air-entraining agent also improves the frost and heat resistance of the product, increases the heat and sound insulation effect, and reduces the bulk density of the product.

Hydroxypropyl methyl cellulose is mainly used in construction materials:

The important deciding factor for selecting tile adhesive is the bonding strength, however, both the

substrate and tile surface have water absorption, so in this case, the role of a water retention agent is very important, adding HPMC can well meet this need. HPMC not only has a good water retention effect but also can make the material easy to mix, improve the construction efficiency, extend the open time of tile adhesive, and to a certain extent reduce the construction cost.

Wall putty (skim coat) has gradually replaced other finishing materials. Usually, a small dose of HPMC is added to these materials to greatly improve the construction performance, prevent cracks and make the wall plaster flat and smooth. HPMC also improves the uniformity of the wall putty, making it easier to smooth out, improving sagging resistance, and increasing efficiency.

HPMC and RDP are highly effective additives in joint compounds. They improve their water retention capacity, avoiding strength loss and cracks due to excessive drying and lack of hydration. They also thicken the compound, improving its bond strength and flowability, thus ensuring its stability and workability.

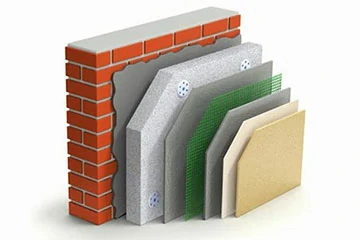

EIFS are insulation boards made of expanded polystyrene or mineral wool as the main material.

Contains an adhesive for bonding the insulation board to the substrate. The addition of HPMC to EIFS improves the processability and bond strength of the adhesive on the one hand. On the other hand it improves adhesion and cohesion, increases flexibility and impact resistance, improves surface abrasion resistance and avoids the formation of cracks and blocks.

HPMC is used in self-leveling compounds to improve their processing and final product properties. (MikaZone can provide customized formulations to meet your specific industrial needs.) It improves the consistency and bond strength of the self-leveling compound, extending the setting time and ensuring better quality over a longer field working time.

The water repellency of self-leveling compounds is also significantly improved with the proper addition of HPMC.

HPMC and HEC can be added to daily chemicals to play the role of thickener, emulsifier, stabilizer, suspending agent, and moisturizer. It can ensure the long-term stability of the liquid, and also helps to control the dosage without causing too much pouring because the liquid is too thin and does not harm the skin. pH value stability is suitable for most detergents.