NOVASTAR™ Powder Defoamers

Fast Defoaming

Rapid foam suppression and control

Long-term Stability

Consistent performance over time

Eco-friendly Formula

Sustainable and environmentally safe

Rapid foam suppression and control

Consistent performance over time

Sustainable and environmentally safe

NOVASTAR™ Series | High-Performance Industrial Solutions

At LANDU, we specialize in producing high-performance powder defoamers for industrial applications. Our NOVASTAR™ series is engineered specifically for dry powder-based systems, including dry-mix mortar, powder coating formulations, detergents, and construction materials.

In contrast to conventional liquid defoamers, NOVASTAR™ powder formulations blend effortlessly into powder systems. They preserve product flowability, maintain a consistent visual appearance, and simplify both storage and transportation.

Advanced Performance | Proven Results | Sustainable Solutions

Leveraging advanced mass-production techniques and centralized raw material sourcing, NOVASTAR™ delivers competitive pricing without compromising quality consistency.

Offers fast, effective foam elimination combined with prolonged suppression, enhancing surface smoothness and improving the overall stability of finished materials.

Integrates effortlessly with cement, mortar, putty, and a wide range of dry-mix systems, ensuring uniform defoaming performance across formulations.

Maintains efficiency even under harsh conditions, including exposure to strong acids, alkaline environments, and elevated temperatures.

Exceptional efficiency means only 1–3 kg per ton of dry-mix mortar is required to achieve optimal results, reducing material costs and waste.

Free from VOC emissions and FDA-certified, NOVASTAR™ supports safer manufacturing processes while aligning with eco-friendly standards.

NOVASTAR™ Powder Defoamer | Technical Specifications

Specialized Solutions for Different Environments | P805 | P806 | P807

As a mature and large powder defoamer manufacturer, LANDU NOVASTAR™ has provided various series of powder defoamers used for different environments, such as acidic conditions, alkaline conditions, and neutral and low-temperature environments.

| Grade | P805 | P806 | P807 |

|---|---|---|---|

| Usage Environment | Alkaline System | Neutral/Acidic System | Low-Temperature Environment |

| Bulk Density | 500±100g/L | 500±100g/L | 500±100g/L |

| Particle Size | 80 mesh | 80 mesh | 80 mesh |

| Moisture Content | ≤5% | ≤5% | ≤5% |

| pH Value | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 |

| Dosage Recommendation | 0.1~0.3% | 0.1~0.3% | 0.1~0.3% |

Superior Performance | Consistent Results | Enhanced Quality

Uniformly distributes throughout dry-mix systems, delivering rapid and effective foam breakdown from the moment mixing begins.

Maintains consistent defoaming performance over time, ensuring reliable results across production batches and storage periods.

Allows cement and mortar to cure naturally without altering setting schedules or compromising structural strength.

Improves the ease of mixing and application, enabling smoother, more efficient mortar spreading.

Minimizes the occurrence of pinholes, craters, and similar imperfections, resulting in a cleaner, more uniform surface appearance.

Preserves mortar plasticity and troweling characteristics, providing consistent handling and application efficiency.

Proven Excellence | Advanced Technology | Global Standards

With years of expertise in powder defoamer production, LANDU operates a mature and scalable manufacturing system. We can deliver large volumes while maintaining strict quality standards.

NOVASTAR™ offers not only powder antifoams but also liquid defoamers. For specialized requirements, our technical R&D team can customize formulas to meet your exact needs.

Our powder defoamers are designed for use in mortar, putty, cement, paints and inks, concrete, and detergents, providing reliable foam control across multiple industries.

Committed to quality, LANDU is ISO 9001 certified, ensuring that NOVASTAR™ powder defoamers are produced according to international standards for consistency, safety, and reliability.

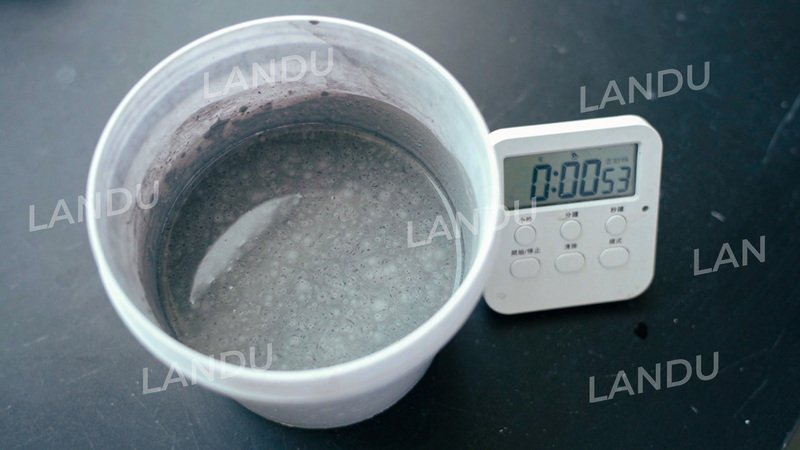

Experience Superior Performance | Test Before You Buy

Are excessive foam and surface defects affecting your dry-mix products?

LANDU's NOVASTAR™ powder defoamers deliver superior foam control, exceptional stability, and seamless compatibility with mortar, putty, cement, coatings, and detergents.

Versatile Solutions | Multiple Industries | Consistent Performance

NOVASTAR™ powder defoamers are engineered for a broad range of dry and semi-dry systems, delivering consistent foam control and improved processing performance across multiple industries and products, including:

Ensures smooth finishes, minimizing air bubbles and enhancing bond strength.

Maintains surface uniformity while preventing pinholes that could compromise waterproof properties.

Controls excessive foaming during production and use, improving efficiency and product consistency.

Reduces foam-related defects for cleaner prints and smoother coatings.

Enhances flowability and surface quality, ensuring a flawless level finish.

Eliminates trapped air to achieve homogenous texture and stronger adhesion.

LANDU NOVASTAR™ Powder Defoamer is designed to control and eliminate foam in dry-mix systems such as mortar, putty, cement-based waterproof coatings, self-leveling concrete, tile grouts, detergents, paints, and inks.

It helps improve surface finish, material stability, and production efficiency across multiple industrial applications.

Unlike liquid defoamers, NOVASTAR™ comes in a powder form that disperses evenly in dry blends, maintains flowability, and offers easier storage and handling.

It integrates seamlessly into formulations without affecting appearance or curing time.

For most dry-mix mortar applications, the recommended dosage is 1–3 kg per ton of material. The exact amount may vary depending on the specific formulation and foam-related challenges.

Yes. NOVASTAR™ Powder Defoamer is VOC-free, FDA-certified, and formulated to meet safety and environmental standards.

It supports safer production conditions and aligns with eco-friendly manufacturing practices.

No volatile organic compounds, ensuring clean air quality

Meets stringent food and drug administration standards

Supports sustainable and environmentally responsible production

Our technical team is ready to help you find the perfect solution for your powder defoamer needs.

Contact Technical Support