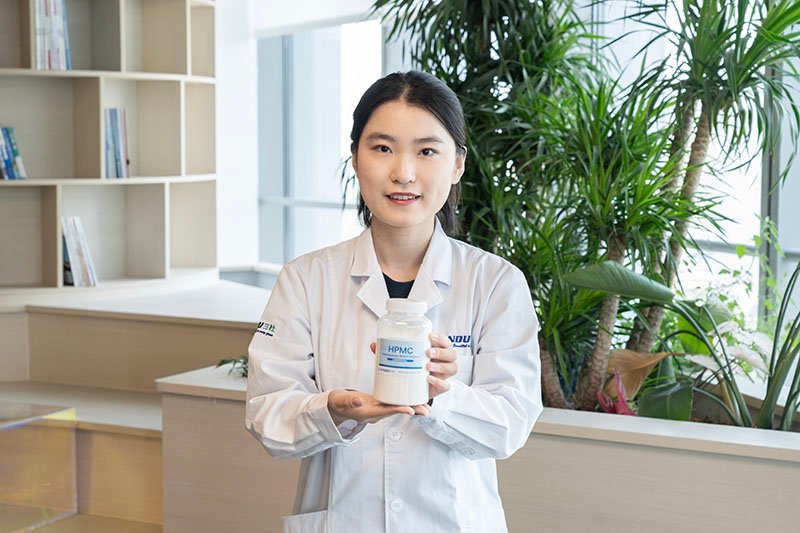

Premium HPMC Manufacturer

Water Retention

Superior moisture control

Workability

Enhanced application properties

Stability

Consistent performance

For more than two decades, LANDU has been a leading name in hydroxypropyl methylcellulose (HPMC) manufacturing in China. Operating under our reputable Landercoll® brand, we specialize in delivering premium cellulose ethers designed to meet the highest industry standards.

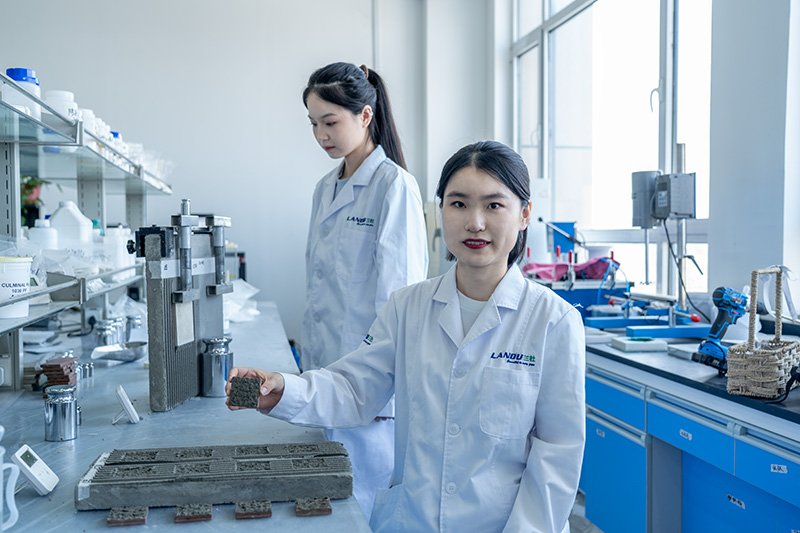

Equipped with state-of-the-art production facilities and dedicated R&D laboratories in Shandong Province, our annual manufacturing capacity reaches 20,000 metric tons. Today, we proudly supply HPMC to customers in over 60 countries, serving a broad spectrum of industries from construction materials to daily chemical applications.

As a top-tier China HPMC supplier, we are committed to consistent product quality, reliable supply chains, and tailor-made OEM solutions that adapt to your specific project needs.

Advanced production lines ensuring consistent quality and efficiency

Dedicated R&D team with decades of industry experience

Negotiable rates based on volume and specifications

Comprehensive inventory with fast delivery worldwide

Superior moisture control technology for enhanced application performance and extended working time

Quick mixing capabilities that save time and improve formulation efficiency

Superior bonding strength ensuring long-term durability and structural integrity

Improved handling characteristics for smoother application and professional finish

Acts as a thickener and binder, ensuring water retention, adhesive strength, and sag resistance in applications such as tile adhesives, wall putty, mortars, plasters, and EIFS systems.

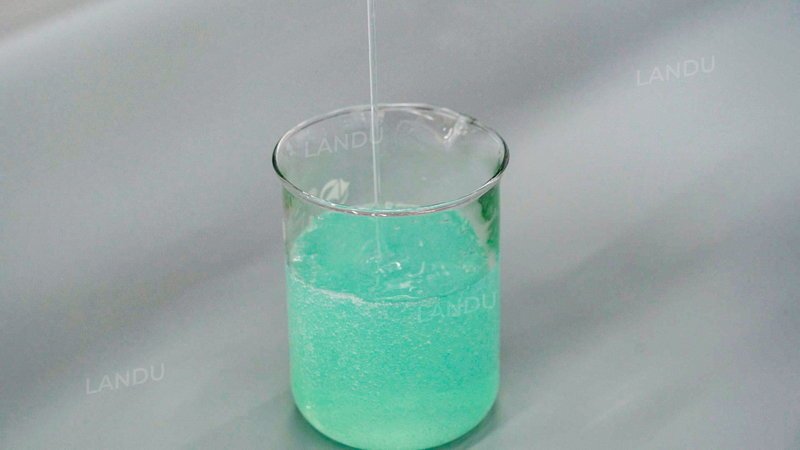

Provides thickening, stabilization, and precise viscosity control—enhancing texture, product stability, and overall consumer satisfaction across personal care formulations.

Premium-grade HPMC powder specifically formulated for cosmetics and skincare applications. Our solutions are tailored to help brands create stable, high-performance products that meet the most stringent quality standards.

Effectively slows moisture loss, ensuring extended working time and improved application performance.

Boosts viscosity for a uniform texture, delivering enhanced cohesion and stronger structural integrity.

Minimizes sliding and sagging, allowing materials to stay precisely where they are applied.

Functions as a dependable binder, reinforcing durability and long-term stability.

Maintains even distribution in suspensions and emulsions, preventing unwanted separation.

Produces a seamless, continuous layer that elevates both functionality and overall product aesthetics.

Our cellulose ether products are widely used in construction materials, daily chemicals, coatings, and industrial applications.

High-quality HPMC products for diverse applications

White to off-white powder

Customized grades available

Landercoll® HPMC significantly enhances the bonding performance of tile adhesives while preventing unwanted lump formation. The result is a strong, long-lasting grip to wall and floor surfaces, ensuring that tiles stay firmly fixed for years without loosening or falling off.

When applied to walls and ceilings, Landercoll® HPMC ensures exceptional water retention and adhesion. This enables gypsum plasters to set into smooth, flawless layers that resist cracking and clumping, providing a stable and uniform finish that stands the test of time.

For both interior and exterior finishing works, Landercoll® HPMC improves the cohesiveness of skim coat and wall putty mixtures. It increases abrasion resistance, creating even, well-bonded surfaces with a refined and polished appearance.

Within cement-based renders and mortars, Landercoll® HPMC plays a crucial role. It ensures superior water retention, better flexibility, extended open time, smoother handling, enhanced crack resistance, and reliable anti-sagging properties — all of which contribute to improved application and durability.

In masonry construction, Landercoll® HPMC improves mixing workability, lubrication, and laying efficiency. It preserves strong bond strength even under heavy loads or horizontal pressure, helping maintain the integrity and reliability of built structures.

For ETICS/EIFS adhesive and embedding mortar formulas, Landercoll® HPMC delivers consistent viscosity, prevents sagging, and reduces unwanted stickiness. The result is a smooth and effortless application process, enabling clean lines and uniform textures across surfaces.

Landercoll® HPMC demonstrates exceptional versatility and reliability across diverse construction applications, delivering consistent quality and performance benefits that professionals trust.

Innovation • Quality • Excellence in Cellulose Ether Technology

With decades of expertise, LANDU has established itself as a prominent manufacturer in the field of cellulose ethers and their derivatives. Our product range has grown far beyond cellulose ethers, now encompassing Redispersible Polymer Powder (RDP), Polycarboxylate Superplasticizer (PCE), Gypsum Retarder, and Powder Defoamer.

LANDERCOLL® was launched under the LANDU umbrella as a brand dedicated exclusively to cellulose ether innovation. Supported by a highly skilled technical team and a fully integrated supply chain, we deliver premium-grade cellulose ethers worldwide.

As a trusted manufacturer of HPMC, LANDERCOLL® stands for innovation, quality, and continuous advancement.

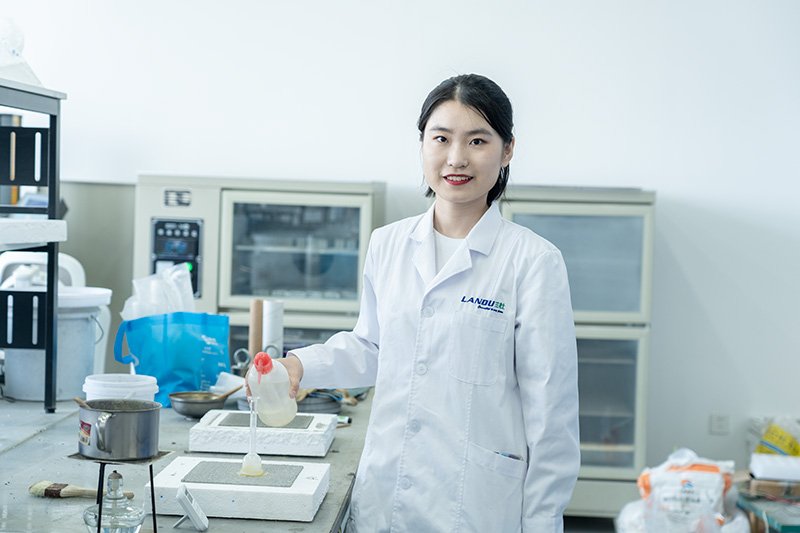

We sustain significant investment in state-of-the-art instrumentation and modern R&D facilities to boost both the performance and consistency of our cellulose ether products. Our laboratories are fully equipped to analyze the physical and chemical properties of HPMC, ensuring each production batch is tailored to meet the precise technical standards of our customers.

State-of-the-art instrumentation and modern facilities

Comprehensive analysis of physical and chemical properties

Each batch tailored to precise technical standards

Manufacturing systems designed for accuracy, stability, and environmental sustainability

Horizontal & vertical reactor equipment

High-precision dimensional vibrating screen systems

Distributed Control System (DCS) for process management

Complete wastewater and exhaust gas treatment technology

CE-certified production facilities ensuring quality standards

LANDERCOLL® has built a robust worldwide distribution network, reflecting our commitment to growth in international markets. We currently partner with general distributors in over 40 countries and maintain exclusive agent relationships in more than 10 regions.

Yet, our journey is far from over—there remain many markets where we are actively seeking new collaborations. We welcome inquiries about our agency programs and look forward to partnering with forward-thinking companies to shape the future of the cellulose ether industry.

Join our global network and shape the future of cellulose ether technology together.

Before and After Your Purchase

Our dedicated sales consultants work hand‑in‑hand with skilled technicians to fully grasp your unique needs and pinpoint the solutions that will serve you best. We offer comprehensive digital guides, video tutorials, and real‑time personalised consultations.

We deliver complete formulation support with free trial samples, detailed technical process documentation and professional guidance to fine‑tune your formulas for peak performance. Our chemists ensure your projects succeed from concept to completion.

Every step of your shipment is tracked and managed by our experienced logistics team. You'll have access to the latest freight updates, giving you full visibility of your delivery timeline. Trust in our dependable, punctual supply chain.

Because your projects deserve absolute consistency. LANDERCOLL® HPMC is crafted in world-class facilities with advanced DCS automated systems, delivering pinpoint control over viscosity, water retention, and purity — every single batch.

Our in-house R&D and application labs put products through rigorous testing before they leave the plant, so what you receive isn't just compliant with global standards — in most cases, it outperforms them.

That's the LANDERCOLL® difference.

Choosing the right grade means getting the results you expect on-site or in production. Here's your quick guide:

Medium viscosity for strong grip and slip-free performance.

Low to medium viscosity for a glass-smooth finish.

High viscosity for unmatched crack resistance and extended open time.

Medium viscosity for superior water retention and durability.

Not sure? Our technical team can match your exact requirements to the ideal HPMC grade — saving you testing time, and ensuring your first try gets it right.

Yes — that's where its true value shines.

Strengthens tile adhesives, smooths wall putty, enhances gypsum, stabilizes self-leveling compounds, and boosts EIFS systems.

Thickens and stabilizes shampoos, body washes, toothpaste, and detergents — delivering rich textures and lasting stability.

One product, many industries — meaning sourcing becomes simpler and supply chains get easier to manage.

With LANDERCOLL® HPMC, materials perform better in every phase:

Preventing premature drying so cement hydrates fully.

Making application effortless and consistent.

Keeping mortar, plaster, or adhesive exactly where you apply it.

Delivering enduring hold even in demanding conditions.

Improving long-term durability and customer satisfaction.

Think of it as the hidden partner behind every flawless finish.

Our HPMC comes from renewable plant sources like wood pulp or cotton linters. It's non-toxic, biodegradable, safe for direct human contact — and widely trusted in sectors as strict as pharmaceuticals.

We protect your investment with:

25 kg multi-layer paper bags with PE liners for maximum moisture protection.

Tailored packaging and private labeling to fit your brand.

Every package is engineered for long-distance, climate-diverse transport — so product integrity is never at risk.

Measures viscosity, moisture, pH, ash levels, and substitution rates.

Tests how the product actually performs in real-world mixes.

Only after passing both do we ship. This is why customers worldwide trust LANDERCOLL® to deliver the same performance, every time.

7–10 days to your door

15–20 days

With 3 production facilities and 20,000 MT annual capacity, we keep lead time short — because we know downtime is not an option.

Yes, and it's one of our strongest value-adds:

Free of charge

With in-depth formulation reports

Video demos and best practice guides

From seasoned chemists & engineers

It's simple: tell our sales team your application, viscosity preference, and any performance targets. We'll send free samples so you can test the quality in your own process — plus technical support to help you achieve the best results before committing to bulk purchases.