Premium Quality

Premium Quality

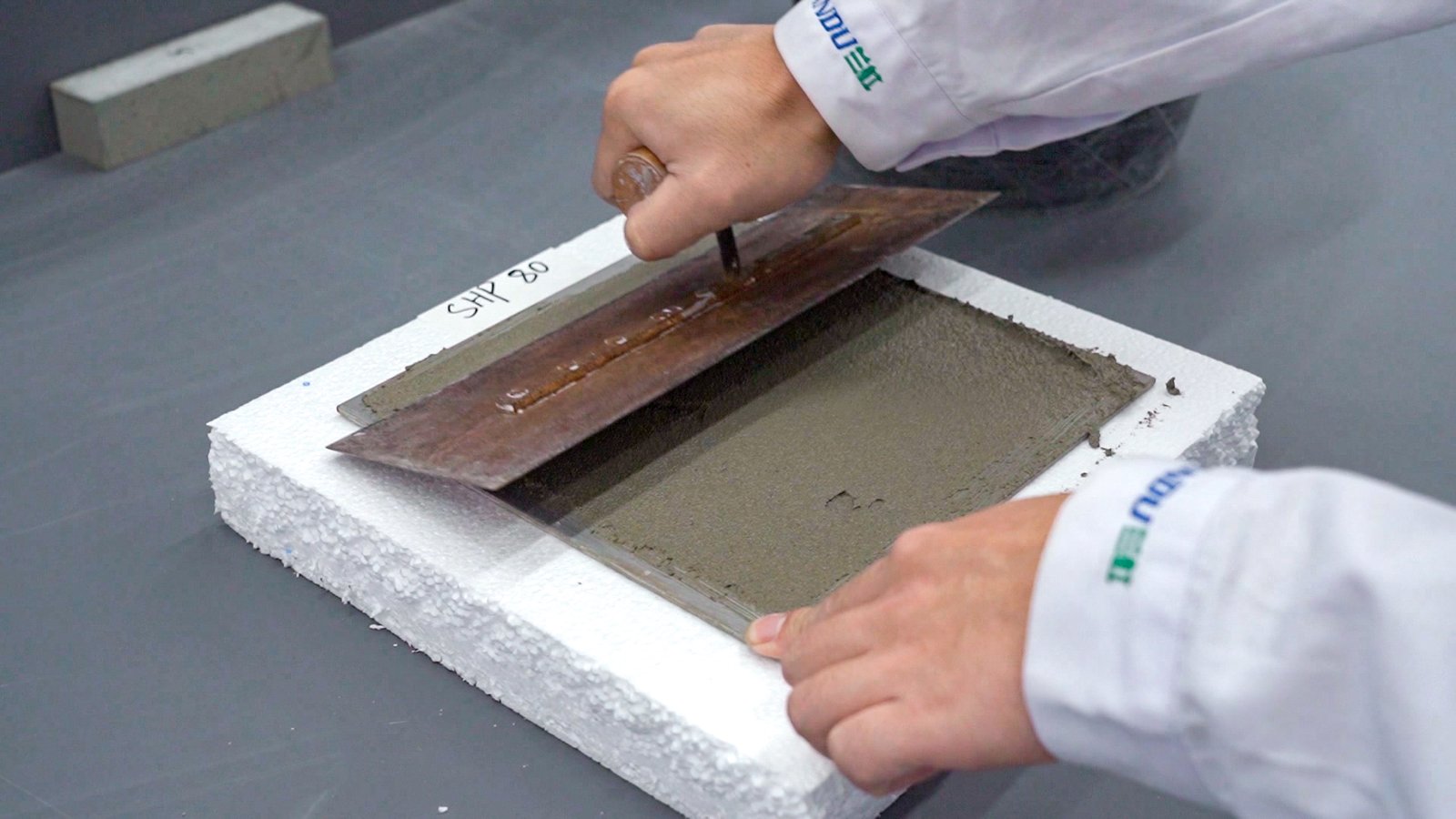

Try LANDU Quality First

Free Sample Program

Test our full additive range in your own mortar design. Experience the LANDU difference with our comprehensive sample package.

Complete Sample Set

200 – 600 g of each additive type

Technical Documentation

Full brochure and data sheets included

Formulation Support

Personalized adjustment guidance

Expert Consultation

Direct access to LANDU engineers