Request Your Free Sample Now

Global Express Delivery via FedEx / DHL

High‑Performance Polymer Additives for Cementitious Waterproofing Systems

Waterproof mortar is a cement‑based mixture designed to prevent moisture penetration while maintaining strong adhesion and durability. Commonly used in basements, bathrooms, water tanks, swimming pools, and exterior walls, it forms a dense layer that resists water ingress.

Unlike ordinary mortar, waterproof mortar contains functional chemical additives—such as cellulose ether (HPMC / MHEC), redispersible polymer powder (RDP), and polycarboxylate superplasticizer (PCE)—that enhance impermeability, flexibility, and long‑term strength.

Blocks moisture penetration

Resists cracking & movement

Durable protection

Performance additives are crucial for achieving a truly waterproof, crack‑resistant mortar. They modify the cement matrix to improve bonding, flexibility, and surface durability.

Cellulose Ether

Redispersible Polymer Powder

Polycarboxylate Ether Superplasticizer

LANDU additives are designed for modern cementitious waterproofing applications, including:

With their advanced chemical properties, our additives provide reliable performance across varying cement types, sand gradations, and climatic conditions.

Professional waterproofing

Moisture protection

Water-resistant coating

Long-term sealing

Weather resistance

Protective overlay

Complete chemical solutions for high-performance waterproofing systems

Cementitious Rheology Modifier

LANDERCOLL® HPMC K200 offers superior moisture retention and smooth application performance. It ensures steady curing, improved bonding strength, and even mortar consistency, making it essential for waterproof and repair mortars.

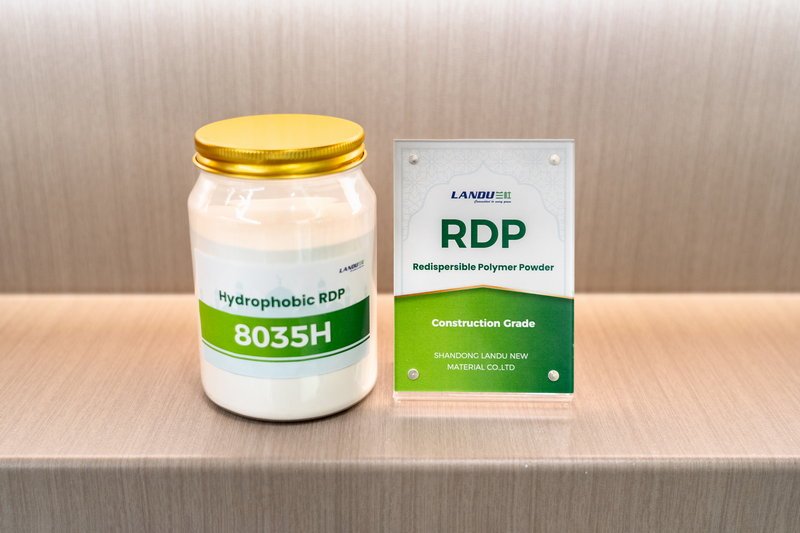

Hydrophobic Redispersible Polymer Powder

ACCURATE™ 8035H RDP enhances mortar flexibility and adhesion while imparting superior hydrophobic properties. It is widely recommended for exterior coatings, bathroom walls, and waterproof plaster formulations.

High‑Range Polycarboxylate Superplasticizer

LANDU PCE 570P reduces water demand while increasing flowability and compactness. It helps create high‑density mortars with superior impermeability and cohesion.

SHP - Surface Water Repellency

NOVASTAR™ SHP forms a protective hydrophobic barrier inside the mortar matrix, preventing water absorption and minimizing efflorescence.

Air Elimination Additive

Defoamer minimizes air entrapment during mixing for a dense, uniform surface—essential for decorative waterproof mortars.

| Additive | Typical Dosage Range | Application Remarks |

|---|---|---|

| HPMC / MHEC | 0.2 – 0.5 % by cement weight | Improves water retention and open time |

| RDP 8035H | 2 – 5 % | Enhances flexibility and hydrophobicity |

| PCE 570P | 0.3 – 0.8 % | Reduces water demand for denser mortar |

| NOVASTAR SHP | 0.2 – 0.5 % | Adds surface water repellency and anti‑efflorescence |

| Defoamer | 0.05 – 0.2 % | Removes air bubbles for smooth finish |

Actual dosage depends on sand gradation, cement type, and performance target. For optimization, please consult LANDU's technical team.

in cellulose ether and polymer technologies

HPMC, MHEC, RDP, PCE, SHP, Defoamer

manufacturing facilities

for various climates and raw materials

with global logistics network

MVR, DSC, and SIS analysis for consistent quality

Test LANDU additives directly in your waterproof mortar formulations to validate performance before ordering in bulk.

for formulation improvement and application testing

for waterproof systems and cementitious coatings

based on local material analysis and performance benchmarks

to ensure seamless production integration

Waterproof Mortar Additives

Use a combination of RDP 8035H and HPMC K200 for optimal bonding and flexible waterproof films.

Add NOVASTAR™ SHP hydrophobic powder and PCE 570P for higher density and water repellency.

Typical usage is 0.2 – 0.5 % by cement weight depending on viscosity and workability.

Yes. Our R&D team supports full formulation development and performance optimization.

Absolutely. LANDU provides 200 – 600 g sample kits along with comprehensive TDS and consultation.

Yes. All LANDU additives are manufactured under ISO 9001 and EU REACH compliance standards.

Our technical team is ready to assist you with customized solutions and expert guidance.

Test our additives in your actual formulations

Customized solutions for your specific needs

Build your brand with our quality products

Global logistics with expert support